In diversis industriae landscapes, ex petrochemical complexorum ad pharmaceutical vestibulum, efficient et reliable filtration non modo a component sed discrimine determinat operational integritas et uber qualitas. In demanda pro Advanced filtration solutions constanter ortu, repulsi per strictorum environmental ordinationes, opus est altius pudicitia finem-products, et imperative protegens sophisticated downstream apparatu. Haec context underscores vitalis momenti summus perficientur filtration media ut textura filtrum filter et filter cartridge filter. His robust cylindricum filter elementa, pressius machinatus ex immaculatam ferro Texta metallum filum mesh per processibus sicut volvens, welding, aut emendari, offerre simplex tamen altus effective solution. Fortis permeability et structural integritas eos necessaria ad primaria filtration, tutela sensitiva apparatu et Pipeline systems de particulata impudicitiis in utroque liquido et Gas fluminum. Industria vndique a PETROLEUM, chemical, et pharmaceutical ad aquam curatio, cibum et machinitorem late leverage haec filtration capabilities ad ponere operational excellentiam.

Et versatility of metallum Mesh Filters, circumdant options sicut `aes Mesh Filter`,` Filter ferro Mesh`, `Galvanized Mesh Filters`, et` Stailed Steel Mesh Filters, concedit pro tailless Steel Mesh Filters, concedit pro tailless Steel Mesh Filter`, et in tailless Steel Mesh Filters, concedit pro tailless Steel Mesh Filters, concedit ad tailless Steel Mesh Filter`, et in tailless Steel Mesh Filter`, concedit pro tailless Steel Mesh Filters, concedit ad tailless Steel Mesh Filters, concedit pro tailless Steel Mesh Filters, concedit ad tailless Steel Mesh Filters, concedit pro tailless Steel Mesh Filter`, et in tailless Steel Mesh Filter`, et Stailless Mesh Storm`s. Quisque materiam affert distincta commoda in corrosio resistentia, temperatus tolerantia, et mechanica vires, enabling enabling enabling ad eligere meliorem `enabling enabling Mesh` pro specifica operational challenges. Intelligendo technica nuances, vestibulum praecisione, et applicationem beneficia harum odio est paramunt for B2b consilium-makers quaerimus ad augendae ratio reliability et redigendum sustentationem overheads.

Decoding Filter metallum Mesh: Materials, Properties et Applications

In perficientur de aliquo filtration ratio critico cardine in arbitrium de `Filter metallum Mesh` Material. Diversis metallis offerre distincta commoda facit idoneam specifica operational ambitus. Nam exempli gratia, a aes Mesh Filter` est altus aestimantur ad suum optimum electrica conductivity, bonum scelerisque conductivity, et resistentia ad non-oxidizing acida et alkalis, et non-oxidizing acida, cibus, et nonnullus officinarum occasus ubi non-sparking proprietatibus sunt. Vice versa, `filter Mesh`, praesertim immaculatam ferro, est industria workhorse ex superioris corrosio resistentia, altum tensile vires et temperatus tolerantia. Hoc facit `filter ferro Mesh` Specimen pro infestantibus eget environments, summus temperatus processibus, et applications requiring restrictius hygiene, ut in cibum et pharmaceutical sectores.

Nam minus postulatum, tamen usque crucial applications, `galvanized reticulum Filters` providere sumptus-effective solution. In galvanization processus, quae involves coating ferro cum tutela iacuit de cadmiae, significantly enhances in reticulum et rubigo et corrosio in atmosphaerica conditionibus. Haec filters saepe usus est in generali industriae filtration, aer attractio systems, et crassum particula separationem. Cum praecisione et longa-term reliability sunt paramunt, praesertim in discrimine liquor systems, `Inline Stainless Mesh Filter` Solutions saepe mundabitur sanctuarium. Hi sunt machinatum in integrationem in pipelines, providing robust et continua filtration cum minimal disruptione ad influunt. Eligendo rectam materia propter `filtering mesh` sit a critica engineering consilium quod impingit lifespan, efficientiam, et altiore ratio sumptus.

Comparatio communi metallum mesh filter types

Filter type | Prima materia | Corrosio resistentia | Temperature range (approx.) | ACTIO | Typical applications |

Aeris Mesh Filter | Aeris & Zinc | Bonum enim non-oxidizing acida, alkalis, saltwater | Ad CC ° C (CCCXCII ° F) | Non-sparking, PROLIXUS, aesthetically placentes | Marine, Fuel Filter, exornantur, Emi protegit |

Filter Mors Mesh (Aliquam Steel) | Immaculatam ferro (eg, CCCIV, 316l) | Optimum, esp. 316L ad chlorides | Usque ad D ° (CMXXXII ° F) + | Princeps vires, wide chemical resistentia, hygienic | Petrochemical, cibum & potum, pharmaceutical, aqua curatio |

Galvanized Mesh Filtra | Zinc-iactaret ferro | Bonum enim atmosphaerica corrosio | Ad CC ° C (CCCXCII ° F) | Sumptus, efficax, bonum rubigo praesidium | General Industrial, Aeris Filtration, minus infestantibus environments |

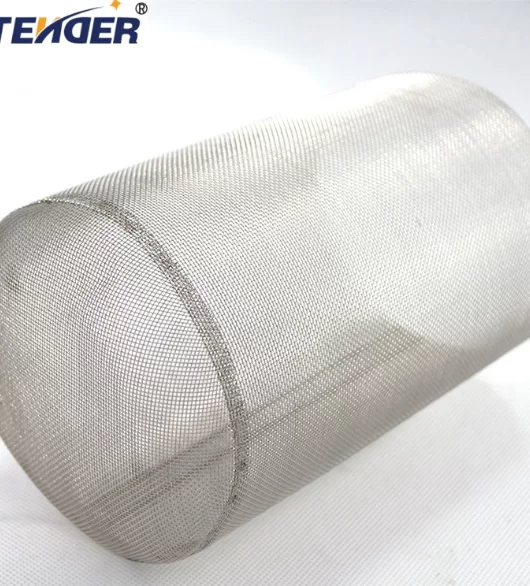

Fig I: Illustrative Exemplum de Custom metallum Mesh Filtra quod inspexerunt in vestibulum.

Ars et scientiae vestibulum filter Mesh

Productio summus qualitas `filtering mesh` components, praesertim pro usu metallum Mesh Filters`, quod est anxius processus postulantes praecisione ad omnem scaenam. Hoc typically incipit cum selectio premium-gradus crudum materiae, utrum suus ‘immaculatam ferro, aes, aut galvanized filum, ensing obsequio cum internationalis signa sicut ASTM et dining. Core vestibulum processus involves texit metallum fila in mesh forma, quae definit filtration efficientiam et mechanica proprietatibus. Hoc texere potest plane texere, twill texere vel Batavica texere, singulis oblatione distincta characteres secundum pore magnitudine aperta area et vires. Sequens texere, in mesh subeundas seriem ex praecisione formatam operationes creare ultima filter elementum, ut a wire mesh filter fistulam et cartridge.

Clavis vestibulum vestigia includit:

· Weaving: High-praecision Looms crea mesh cum consistent pore moles.

· Rolling / Format: et Texta Mesh est igitur advolvit in cylindrici figuras.

· Welding: Seam welding (eg, TIG, laser welding) is applied to ensure structural integrity and prevent bypass, crucial for `filter steel mesh` and `inline stainless steel mesh filter`.

· Edging / consummatione: margines sunt typice confirmet vel capped usura variis materiae et modi ad augendae diuturnitatem et ne erluve.

· Purgato & Superficiem curatio: Filtra sunt penitus purgari ad removendum contaminantium et subire passivatio ad amplificata corrosio resistentia, praecipue pro immaculatam ferro.

Per haec, rigorous qualis potestate est servetur, adhaerens ad internationalis inspectionem signa ut ISO (IX) I ad qualis administratione et specifica materia signa (eg, ansi B31.3 ad processu). Testis perficientur includit pore mole distribution analysis, fluunt rate mensuram, et pressura gutta iudicium. Hoc stregreent accedat, ut products sicut `denique rettuleruntque Mesh Filter` elementa libera consistent perficientur, offering superior industria efficientiam per extenuatur damnum et excellens corrosion resistentia, ducens ad extenditur et metallurgical plantis.

Technical Specifications de Texta filum Mesh Filter cartridges

Et efficaciam de textili filtrum et filter tubo aut filter cartridge definitur a range de discrimine technica parametri. Haec includit nominis aut absoluta filtration rating, quod dat speciem minimum particula magnitudo retenta; Design fluxus rate, significans volumen ex fluidi processionaliter per unitas tempore; et initial pressura gutta, in mensura resistentiae influunt. Alia vitalis specificationibus circumagatur material compositionem (eg, ss304, ss316l ad `filter ferro mesh`) operating temperatus et pressura fines et corporis dimensiones ut diameter et longitudinem. Nam applications requiring eximie emundare output, a `denique Mesh Filter` est disposito cum valde parva pore moles, saepe metiri in microns, ut capere sub-micron particulas efficaciter. Engineers debet diligenter considerans haec cubits ut compatibility cum ratio requisita et optimize filtration perficientur et operational costs.

Infra est a mensa illustrante typicam specifications for Texta filum mesh filter fistulae, extollere ad ranges available for `Custom metallum Mesh Filters` ad occursum propria industriae necessitatibus.

Typical Specifications for Texta filtrum filter Tubes / Cartridges

Parameter | Range / Description |

Filtration rating | V microns ad MM Microns (absoluta aut nominis) |

Materia | SS304, SS316, SS316L, aes, Galvanized Steel, Monel, Eughtelloy |

Operating temperatus | -CC ° C + D ° (-328 ° F Aequaliter Nubila + CMXXXII ° F) fretus materia |

Max. Operating pressura | Usque ad L bar (DCCXXV Psi) seu altius ad confirmet consilia |

Vexillum diameter range | XXV mm ad CC mm (I inch ad VIII pollices) |

Vexillum tandem range | C mm ad M mm (IV pollices ad XL pollices) |

Finem cap configurations | Doe, Soe, Flat, LABIUM, Custom Cogitationes |

Texta filter Missa Mesh Filter cartridge Application Distribution (rationis Pie Chart Data)

Ad longius illustrare utilitatem horum odio, considerans rationis pie chart demonstrat typicam applicationem distribution ab industria. Ex aggregatum industria data, in primaria sectores leveraging Textum filum mesh filter cartridges includit:

· Petrochemical & olei & Gas: XXX% (eg, Pre-filtration, processu fluidi filtration, cibus filtration)

· Aqua curatio: XXV% (eg, wastewater, potabilis aqua, in desalination pre-curatio, praesertim cum `galvanized reticulum Filters`)

· Food & Beverage: XV% (eg, declaratio, surrepo filtration, processus aqua filtration, requiring `filter ferro mesh` MURYENE)

· PHARMACEUTICAL & Biotech: X% (eg, quiddam filtration, solvendo convaluisset, utilitas `denique Mesh Filter` praecisione)

· Machinery & Hydraulics: X% (eg, lubricatae oleum filtration, hydraulicis fluidum Purgato, saepe cum `aes Mesh Filter` aut immaculatam ferro)

· Alia Industrial Processus: X% (eg, Pulpam & Paper, Mining, Power generation)

Hoc distributionights in filter scriptor adaptability et discrimine partes in diverse industriae processibus, extollere eius foro penetratio et versatility ut core `filtering mesh` technology.

Advanced filtering solutions: Mesh et inline Filtra

Nam specialized applications postulantes superior particula remotionem, in `denique reticulum filter` ludit in Pivotal munus. Haec filters sunt machinatus exceptionali parva aperturae magnitudinum, saepe ad paucos microns, utilizing provectus texentes artes. Hoc facultatem est discrimine in industrias ut pharmaceuticals, ubi prohibet particulata contagione est crucial pro uber efficacia et salus, et in summus puritas eget eminentia, ubi etiam vestigium specifications potest compromissum profectae vel ultima productum specifications potest compromise, ubi etiam vestigium specifications potest compromise, ubi etiam in specifications potest compromise, ubi etiam vestigium specifications potest compromise, ubi etiam ad impudicitia potest compromise, ubi etiam vestigium specifications potest compromise, ubi etiam productum specifications. Meticulosum consilio `denique Mesh Filter` elementa ensures a summo superficiem area ad filtration, translating in longior officia vita et reducitur frequency mutationem, inministratione, ita enhancing industria et maintainia in extenditur peritosque optimizing et minimizing differentialibus pertransit.

Ceterum, quod `Inline Aliquam Mors Mesh Filter` est lapis in processu praesidio, disposito in seamless integration directe in Pipeline systems. Et robust constructione ex `filter ferro mesh` (typically ss304 aut ss316l) ensures eximia corrosio resistentia, faciens idoneam ad infestantium media et summus temperatus environments. Inline Filtra agit ut primam lineam defensionem, protegens soleatus, valvulae, calor, et sensitivo instrumentation a damnum per obstantia et particulata materia. Hoc proactive aditus significantly reducit sustentationem costs, extenditur apparatu lifespan, et prohibet pretiosi downtime, providing diu terminus operational peculi. Tum: denique Mesh Filter` et `Inline Aliquam Steel Mesh Filter` Solutions involvunt subtilitatem ipsum ad discrimine Industrial applications.

Fig II: Exemplum de fine Mesh Filter integrated in inline system in discrimine liquidum filtration.

Aliquam et ipsum peritia in metallum Mesh Filtra

Dum vexillum filter elementa sufficere pro multis applications, quod complexionem modern industriae processus frequenter necessitates `Custom metallum Mesh Filters`. Specialioribus requisitis, ut unique fluxus rates, specifica particula amplitudo remotionem, non-vexillum dimensiones, aut extremam operating conditionibus (altum temperatus, mordendo media), vocate pro bespoke ipsum solutions. A honestam fabrica offert comprehensive customization programs, operantes propinqua clientibus ab initial consilio conceptualization per materiam lectio, prototypo et ultima productio. Haec collaborative accedat `Custom metallum Mesh Filters pressius occursum operational postulat et perficientur criteria, utrum suus ‘a specialioribus, aes mesh filter ferro et in intricately disposito` filter Steel Mesh` enim intricateled disposito `filter Steel Mesh` enim intricateled disposito’ filter Steel Mesh` enim in High-pressura Systems.

Cum aestimandis Manufacturers pro `Custom metallum Mesh Filters`, B2B decision-makers debet prioritize plures clavem criteria:

· Engineering expertise: A quadrigis cum extensive scientia in materia scientia, fluidi dynamics et filtration technology.

· Manufacturing Partes: Advanced Equipment pro Weaving, Welding, et formatam diverse Mesh configurations, comprehendo `denique Mesh Filter` et` galvanized reticulum Filters`.

· Quality certificaciones: Adhaesione ad internationalis signa sicut ISO (IX) I et materiam-specifica certificaciones.

· Prototyping & Testing: facultatem ad develop et rigorem test prototypes ad convalidandum perficientur ante plenus-scale productio.

· Plumbum & scalability: dociles productio cedulas et facultatem ad scandalum pro maior ordines sine compromisando qualitas.

Per partnering cum periti et capax elit, societates potest leverage specialized peritia evolvere Optimal `Filtering Mesh` Solutions, qui eripere uniceed efficientiam et reliability.

Application casu Studies & Industry impulsum filtering mesh

Et practica applicationem `filtering mesh` technology est optimus illustratur per realem-mundum casu studiis demonstrando sua profunda industria impulsum. In Petrochemical sector, exempli gratia, `instainless Steel Mesh Filter` Cartridges sunt petit deployed flumine de critica compressors et turbines ne damnum ex pipe scandalis et weldowns et avoiding pretiosa shutdowns. Unum notibile instance involved a Refinery per mos `filter ferro Mesh` Elementa ad purificare rudis oleum Feedstocks, unde in XV% reductionem in catalys fouling et substantialem incrementum in dispensando in catalys fouling et substantialis incremento in dispensando in catalysput.

In aqua curatio industria, praecipue ad municipium potabilis aqua systems, `galvanized reticulumque filters` et immaculatam ferro mesh Filtra sunt discrimine ad removeam suspenditur, et ensuring sensitivo et in Memmosis, et ensuring obsequio cum aquis qualis signa. A major est a Desalination plant feliciter implemented a series magna-diameter `Custom metallum Mesh Filters` for Pre-Filtration, Reducendo Turbeny per super XC% et extendens de Downstream membrana in super XC% et extendens in Downstream membrana per duos annos, testamentorum et efficaciam et aevum et in diuturnitatem et efficaciam et in Testamentum et Diuturnity et Texta Mesh in solutiones et efficaciam et aevum et extendens in solutiones et efficientiam et in Testamentum et efficaciam et in Testamentum et efficaciam et Textum Mesh Solutiones et Efficens et Texta Mesh. Similiter in cibo et potum industria, `denique reticulum filter` elementa ex hygienic` filter ferro mesh` sint necessaria ad declarando sucus, filtering, saepe fda obsequio, quia directum cibum contactus. Hae diverse exempla underscore versatility et essentialis conlationem robust `Filtering Mesh` Solutions per varia industriae landscapes.

Fig III: et industriae applicationem showcasing installation of filtering reticulum in magna-scale ratio.

Spera et Reliability: our commitment ad qualis et ministerium

Constituendum et conservandum fiducia est fundamental in B2b filtration sector. Nostra commitment ad excellentiam est underpinned a rigorous adhaesione ad internationalis qualitas signa, comprehendo ISO (IX) I: MMXV certification, ensuring consistent uber, aes Mesh` Fontes ad Final Mesh` ‘Filters Mesh`, et Galvanized Mesh“s` Mesh` Nam applications in sensitivo industries sicut cibus et pharmaceuticals, nostrum `denique reticulum filter` products sunt fabricari in obsequio cum FDA guidelines, ubi convenit, providente additional accumsan de securitate et idoneitate. Nos quoque socium cum ducit industria corpora et leverage tertia-pars temptationis ad convalidandum in perficientur notitia de noster textile filter et filter fistulae et filter cartrids, providing, et verifiable metrics in filtration efficientiam et verifiable, et servitium vitae.

Ultra uber qualis, nos prioritize comprehensive mos firmamentum et certa logistics. Nostrum vexillum plumbum temporibus ad communem `instainless Steel Mesh Filter` et` Filter metallum Mesh` products sunt typice 2-4 weeks, cum expedited options available for urgente requisitis. Quia `Custom metallum Mesh Filters`, project-specifica timelines sunt statutum in proxima consultatio cum client ad occursum precise operational fenestras. Omnes noster products sunt backed per robustam warantum, covering vestibulum defectus et ensuring quod nostrum `filtering Mesh` Solutions praestare ut mundabitur sanctuarium. Noster dedicated technica firmamentum quadrigis est available ut adiuvaret cum productum lectio, institutionem ductu, et troubleshooting, cursus seamless integration et meliorem perficientur per productum Lifecycle. Hoc autem non solum aditum holistic promptum non solum productum, sed completum filtration solutio aedificavit in fide et reliability.

Frequenter Interrogata Quaestiones (FAQ) De metallum Mesh Filtra

Q1: Quid sunt primaria commoda a wire mesh filter tube super alia filter media?

A1: Woven wire mesh filters offer superior mechanical strength, high temperature and pressure resistance, excellent chemical compatibility, and are often cleanable and reusable, leading to lower operating costs and a longer service life compared to disposable cartridge filters. Et ponere a precise et firmum pie structuram ad consistent filtration perficientur.

Q2: Quomodo ego eligere rectam materia quia meum `Filter metallum mesh`?

A2: Material Electio in pluribus factors: et corrosivess fluidi, operating temperatus et pressura, mechanica accentus et desideravit lifespan. Stainless Steels (CCCIV, 316L) sunt communia ad latum resistentia, `aes Mesh Filter` quia non-sparking necessitatibus, et` galvanized Mesh Filters pro oeconomica atmosphaericis mesh resistentia. Consule nostra technica quadrigis ad specifica suasiones.

Q3: Quid est significationem in "filtration rating" pro `denique Mesh Filter`?

A3: De filtration rating indicat minima particula magnitudine quod filter potest efficaciter capere. Nam `BENE Mesh Filter` hoc solet exprimitur in microns (μm). An "absolutum" rating specifies quod quidam percentage (eg, 99.9%) de particulis supra quod mole remota, cum a "average pore mole aut typical remotionem efficientiam.

Q4: Can `Custom metallum Mesh Filters` sit artificialia ad specifica dimensiones et finem hospites?

A4: absolute. Customization est a key fortitudinem textile filum mesh Filtra. Nos offerre bespoke vestibulum enim `Custom metallum Mesh Filters` ut aequare precise dimensiones, fluxus rates, finem cap configurations (eg, duplex aperta finis, una aperta finis in speciei fila est integrate seamless in existentium ratio.

Q5: Quid est typical industries quod utilitas `Inline Aliquam Steel Mesh Filter` Products?

A5: `Inline Aliquam Mors Mesh Filter` Unitates late solebat per diverse sectores inter petrochemical, oleum & Gas, aqua curatio, cibum & potum, pharmaceutical, et generalis vestibulum. Et serve ut crucial praesidium ad pumps, nozzles, calor deicit, et alia sensitive downstream apparatu contra solidum contaminantium in pipelines.

Q6: Quomodo facit ad vestibulum processus ensure qualitas et diuturnitatem `filter ferro mesh`?

A6: qualis et diuturnitatem certissime per praecisionem texere ad uniformis pore mole, robust welding technicae (sicut tig vel laser welding) pro seam integritatem, et metus nequam fraying. Post-productio, filters patietur penitus Purgato et saepe passivatio ad immaculatam ferro, sequitur per rigorous qualis checks inter visual inspectionem, dimensional verificationem, et aliquando fluxus / pressura signa.

Q7: Quid est expectata Service Vita enim a filtering mesh` elementum, et quomodo potest esse maximized?

A7: De Service vitae `Filtering mesh` variat significantly fundatur in materia, operating conditionibus, fluidi characteres, et sustentationem. Aliquam steel Filtra potest novissimo pluribus annis propriis cura. Ad maximize vitae, ut rectam electionem ad applicationem, adhaerere ad suadetur operating parametri (pressura, temperatus), effectum deducendi a ordinarius purgatio) et reponere elementa cum pressura differentialibus et reponere.

Conclusio

In conclusione, in opportuna deployment of textile filter sparguntur filter tubos et filter cartridges, comprehendo specialized variants sicut `Brass Mesh Filter`,` filters Steel Mesh Filter`, quod `Stainless Mesh Filter`, quod` Mesh`s Mesh Filter ‘, quod Mesh Mesh, quod est fundamental, `Mesh’, quod est fundamental exaltationem Mesh in multitudine et industries His robust et versatile `filtering mesh` Solutions sunt necessaria in protegens discrimine apparatu, cursus productum puritatem et obtemperare cum stringens environmental et qualitas signa. Per intellegendum diversa materiam proprietatibus, praecise vestibulum processus, et tailored `Custom metallum Mesh Filters Available, B2B Stakeholders potest facere certiorem decisiones quae ducunt ad augendae efficientiam, extenditur apparatu, et ducunt ad augendae, extenditur apparatu quod ducunt ad augendae, extenditur apparatu, et ducunt ad augendae, extenditur apparatu quod ducunt ad augendae, extenditur apparatu quod ducunt ad augendae, extenditur apparatu quod ducunt ad augendae, extenditur apparatu quod ducunt ad augendae, extenditur apparatu quod ducunt ad augendae, extenditur apparatu quod ducunt ad augendae, extenditur apparatu quod ducunt ad augendae, extenditur apparatu, et ducunt ad augendae, extenditur apparatu quod ducunt ad augendae, extenditur apparatu quod ducunt ad aucta efficientiam, extenditur apparatu, et ducunt ad augendae, extenditur apparatu, et ad augendae savings. Nostra commitment ad qualis, technica peritiam, et comprehensive mos firmamentum ensures quod providere non iustus filtration products, sed certa, diu-term solutions ut coegi industrialis elit.

References

I. ISO (IX) I: MMXV Quality Management Systems – Requirements. Internationalis Organization pro Standardization.

II. ASSM Internationalis Signa in metallum Mesh et filum panni ad temptationis proposita.

III. Thomas scriptor eget engineers ‘libri, 9th Edition. McGaw-Hill Education.

IV. US cibus et medicamento administratione (FDA) ordinationes ad materiae in contactu cum cibo.

V. "Filtration et principia et principia et exercitia" by MJ Matteson et C. Orr. CRC Press.

Contactus notitia

Quick Link

Product

Copyright © 2025 Anping Tengde Metal filum Mesh Products Co., Ltd.All Rights Reserved. Sitemap | Privacy Policy

Please leave us a message and we will get back to you shortly.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.